Nanjing weiyiji food machinery co., LTD. was established in 2009,We are specialized in providing customers with safe, efficient, energy-saving and environmentally friendly professional mechanical products and systems solutions,it is an expert in systems engineering in the fields of grain and oil food, biology, medicine and chemical industry.The company's service area involves food, grain and oil, biology, chemical industry, environmental protection, milk fat, beverage, beer, starch, cosmetics, essential oil, resin paint and so on.

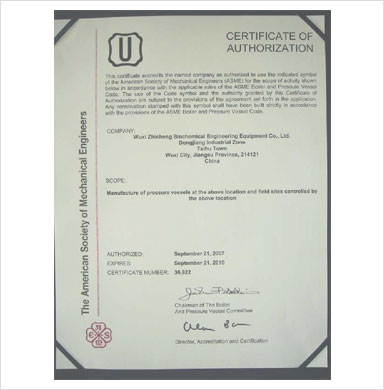

Introduction: the company's manufacturing center, located in yangjian town, wuxi city, jiangsu province, has a strong mechanical equipment processing capability. Has passed the iso9001:2000 quality system certification, and has the pressure vessel manufacturing license. The manufacturing center constantly meets the needs of domestic and foreign markets by introducing advanced foreign technology.